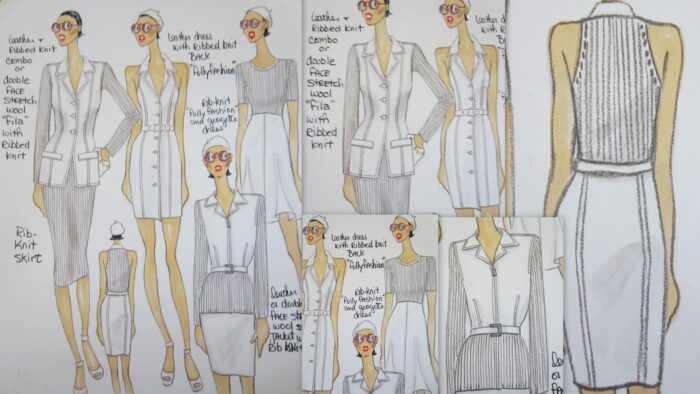

………………….WHITE CLOTHES are some of the most difficult to design and to manufacture……When a sample room or factory is making white clothes the rooms, and the machines have to be spotless. A little dirt or oil from a sewing machine can ruin a garment….When I was designing for QVC there were factories in China that REFUSED to make white clothes, because it was too much trouble. Those that did charged more $$$$$…..The selection of the right fabric for each design was also a challenge…..See through of certain garments was always a problem to manufacture, but many times a lining solved the problem….However, for unlined garments like the cotton poplin wrap trench jacket to the left, and the wrap georgette dress to the right….the insides had to be as clean finished as the outside……Sometimes the seam allowances were piped or turned back enough to be stitched to give the desired clean finish. Sometimes they were just marrow stitched which was not ideal for me……Sometimes price was the deciding factor……Sheer clothes like the georgette dress had French seams…..All of this extra work cost $$$$ which is the reason that sometimes a white garment costs more $$$$ than a color garment…..There is a white unitard under the dress which had its’ own set of manufacturing problems….If a style is sold in white and color, which many are, and a factory charges more for the white to be made, usually an average price is reached for the garments so two different priced don’t have to be assigned. Try and explain two different prices for the same garment to a customer!…..The stretch cotton Pea jacket in the center, and the matching skirt were fully lined, which for me wasn’t ideal, because the lining added weight and made the garments warmer to wear….Also, to make them correctly the lining should be stretch too, or it defeats the purpose of a stretch garment…If a stretch lining wasn’t avail or too costly sometimes extra ease was added to the lining to compensate…Sometimes to get around this problem I would line the front only, half line the back to cover the shoulder pads, and leave the sleeves unlined. I would pipe the exposed back seams and armhole for a clean finish…..It always amused me when certain women would complain that the jacket wasn’t fully lined! They misguidedly thought this was a cheaper way to make a garment…..What they didn’t realize was this was a much more expensive, time consuming way to finish the jackets. Putting a full lining in a jacket covered many sins, but an unlined garment, or partially lined garment had to be clean finished on the inside, which was more labor intensive…..Plus, these half lined jackets were more COMFORTABE and cooler to wear in warmer weather…….Like I always say…….”KNOWLEDGE is a powerful thing!”